Precision bottle tools, known as shrouds in the industry, are a sophisticated type of decorating tool that Schwerdtle engineering and manufacturing excels at.

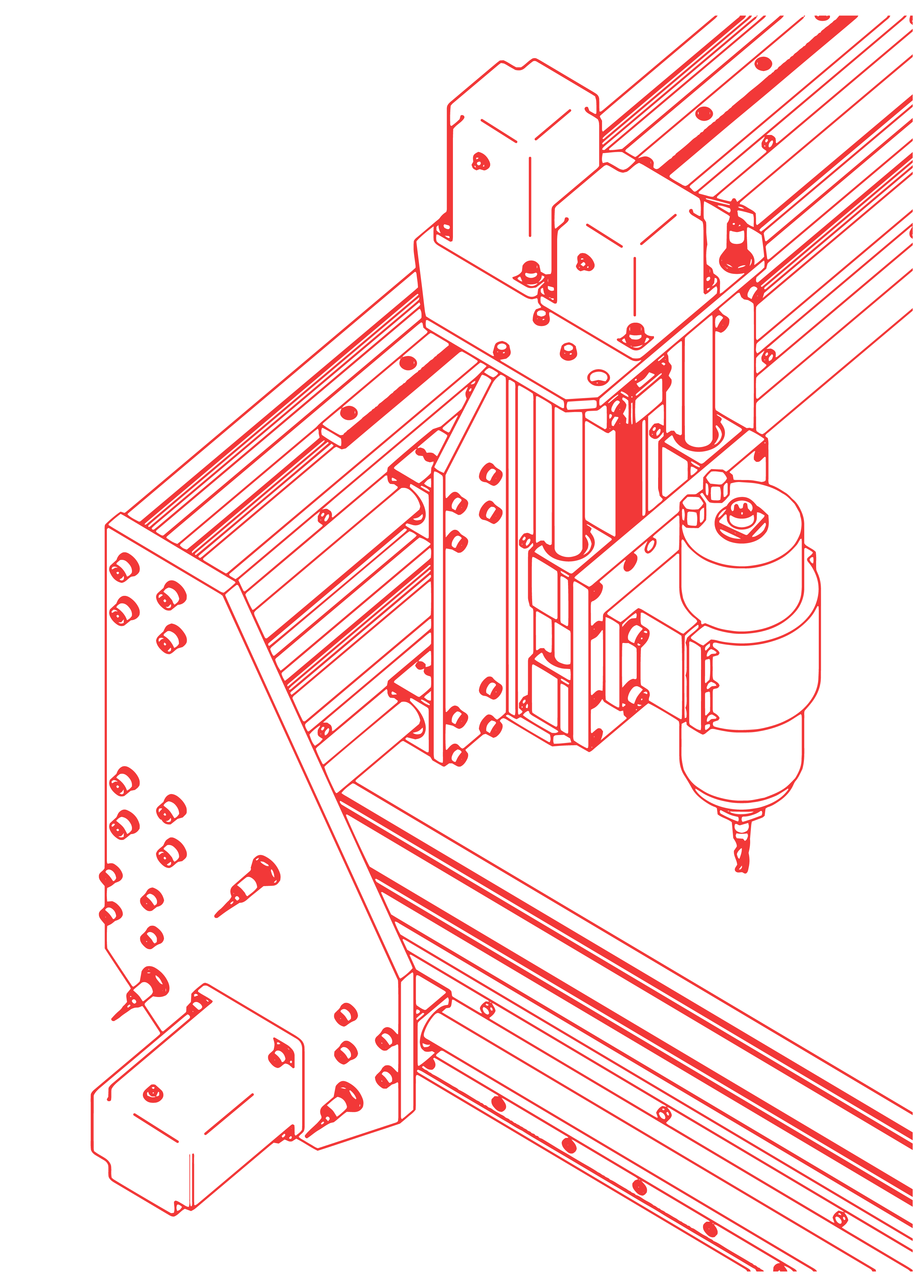

Quick setups and perfect impressions are achieved with Schwerdtle bottle tools and integrated hot-stamping dies. Solid support and proper die clearance between the foil and the part being decorated are critical for accurate hot stamp decorating results. Precision and high-tolerance workmanship produces the perfect hot-stamped image. We do initial setups during the assembly of your tools with your actual parts. Our matched tooling results in minimal adjustment and greatly reduced setup times.

Our toolsets often include heating, cooling, and suction components, a “half-size” shroud is often used for moving and feeding the bottle into the hot-stamp shroud on the assembly line. We engineer and manufacture bottle tools for every application.

How the Bottle Decorating Process Works:

The bottles are clamped into a well-adjusted mold, the foil feeds through a slot and goes across the mold. For proper printing, the foil must touch the bottle before the heated die. When the die descends, the bottle is inflated with air. The bottle expands just enough to contact the die surface where the foil decoration is transferred to the product.

Hot stamping onto bottles is a very difficult and technical operation. Schwerdtle has been providing critical bottle tool sets to our customers for more than 60 years.

Learn more about supplies for Schwerdtle Decorating tools here