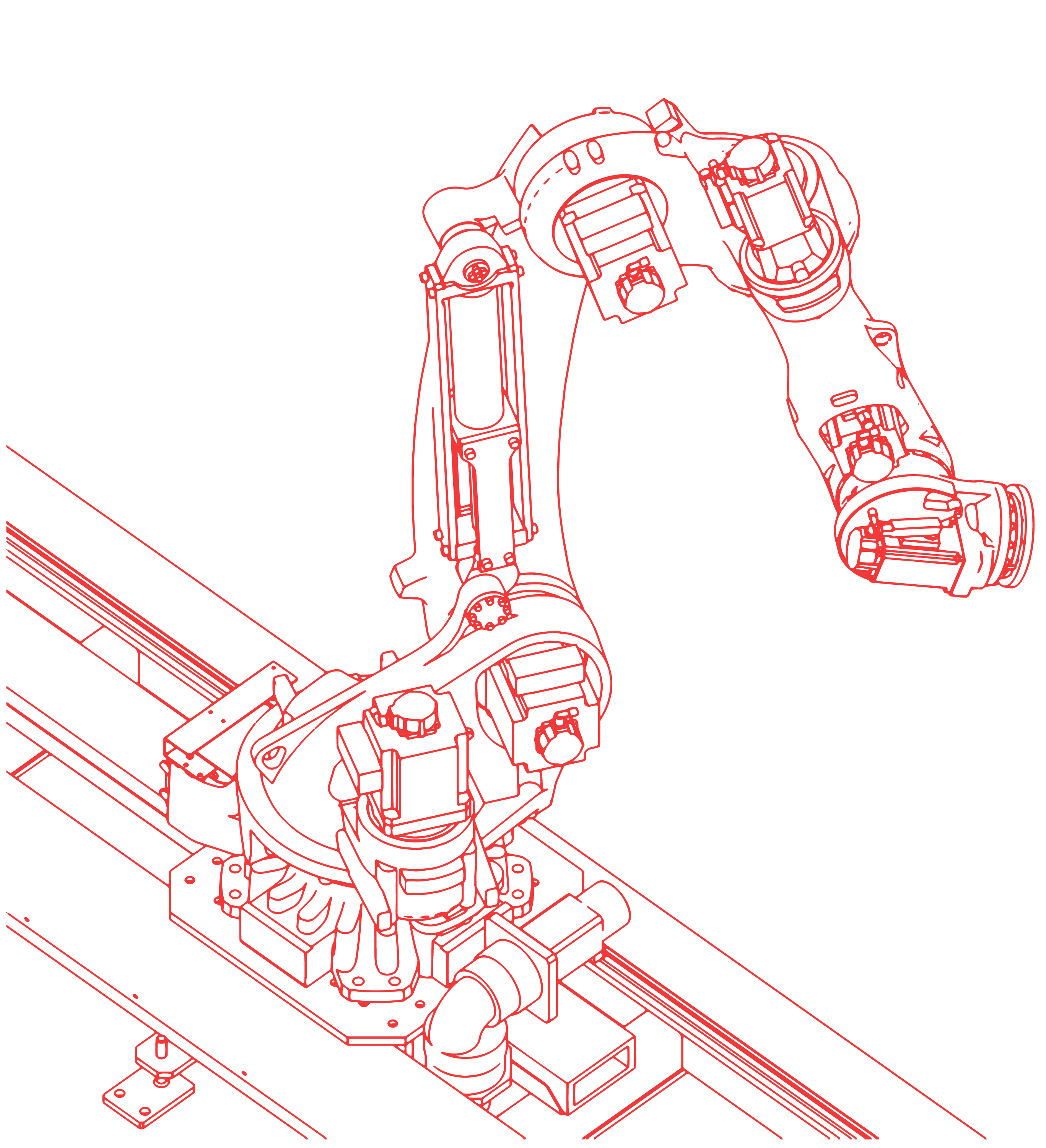

As is true with most of the products Schwerdtle manufactures, our value add in the world of ultrasonic welding comes from our ability to engrave custom, complex three-dimensional designs or surfaces on sonic welding rolls and horns, creating a weld that is both highly function and, at the same time, decorative.

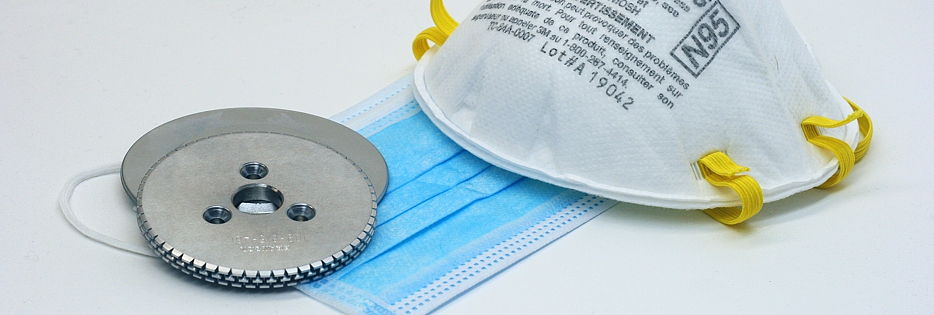

Our clients operate across a wide range of industries – from high-tech to packaging. Ultrasonic welding is favored by high-tech manufacturers because no sparks are produced in the process which may burn electrical components. It is used in the automotive industry to provide extra strength to welds of steering parts, door panels, and many engine components. It is used in medical equipment manufacturing because ultrasonic welding creates no chemical reactions. Finally, it is extensively used in the packaging industry to manufacture different kinds of thermoplastic containers and tubes.

Our depth of experience in 3D surfacing and engraving allows us to create decorative sonic welding tools that are both highly functional and add a distinguished design to your products. Ordinarily, we will receive the sonic welding horn (sonotrobe) and anvil blanks from the customer and engrave decorative designs or complex surfaces into the part. Stitching wheels are made complete. An example is a sonic stitching wheel for assembling a shower curtain. Why have a boring stitch design when you can have a decorative, continuous floral pattern that is both functional and decorative?